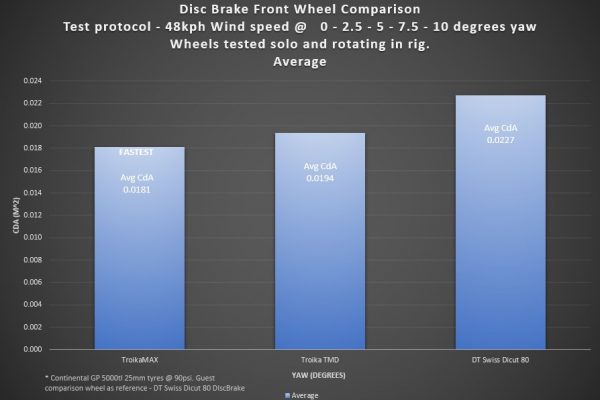

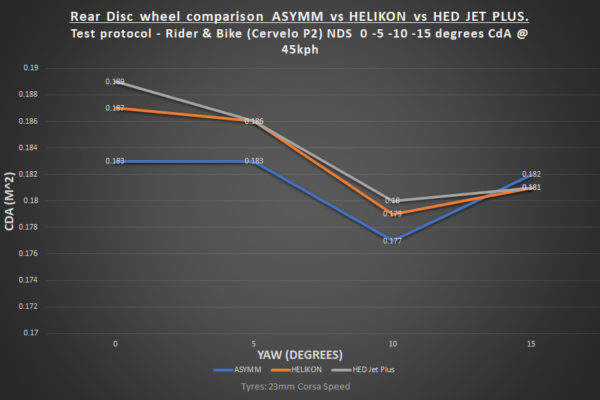

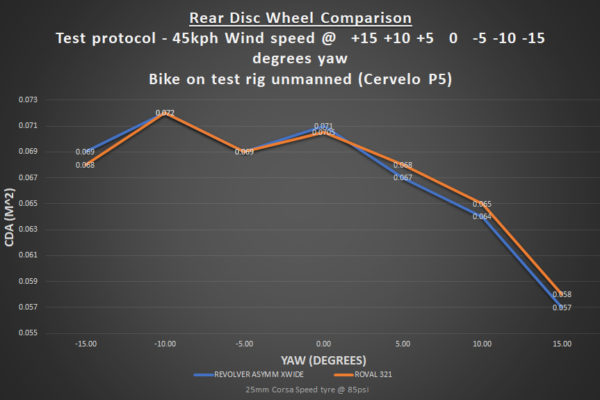

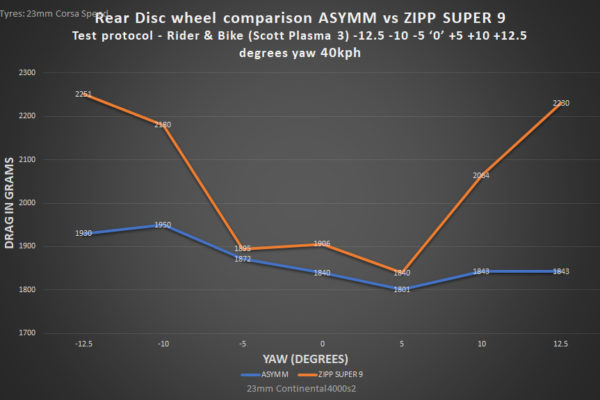

Our aim at Evolve Aero is to continually improve the performance benefits of our products with a rolling programme of aerodynamic research and development. Aerodynamic drag accounts for between 70-90% of the resistance encountered by a cyclist riding on the flat at typical race speeds (35-50kph), the higher the speed the higher the drag created. The potential gains to be made here far outweigh other measurable factors such as weight and rolling resistance, which is why we focus our efforts on aerodynamics in particular. We gather our data using various methods – Wind Tunnel testing, indoor Track testing and outdoor field testing using the latest live aero data analysis, all of which offer a reliable controlled testing environment but have their own strengths in the data they gather. Combining that data helps us to develop wheels and components that perform to the highest level.

Aerodynamic rider positioning and drag reducing equipment in a quest to reduce CdA (Coefficient of drag) has become an arms race and an area where it’s all too easy to fall behind and is often the difference between winning and losing.

Wind tunnel testing

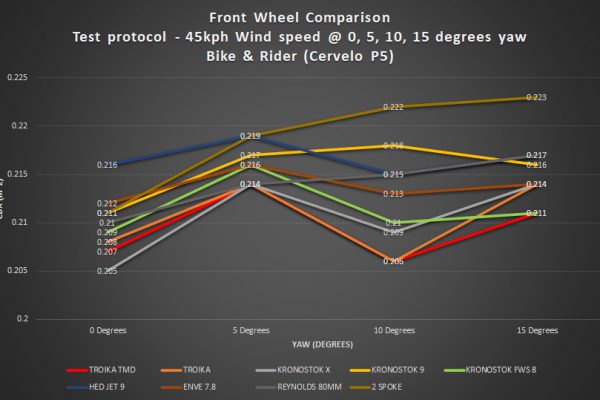

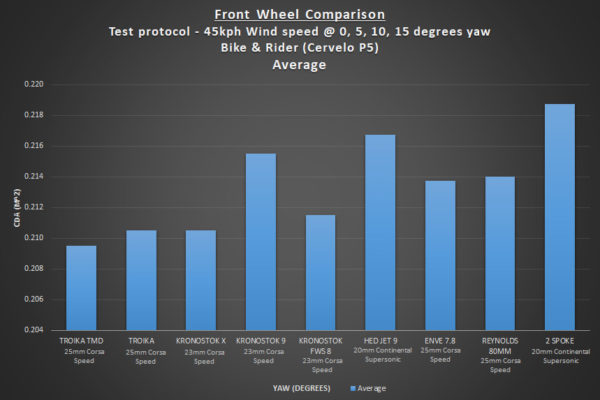

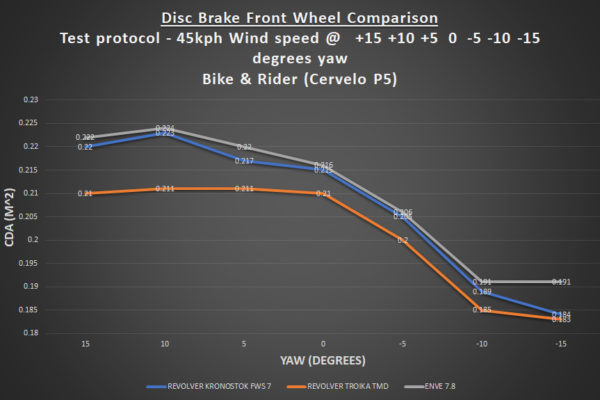

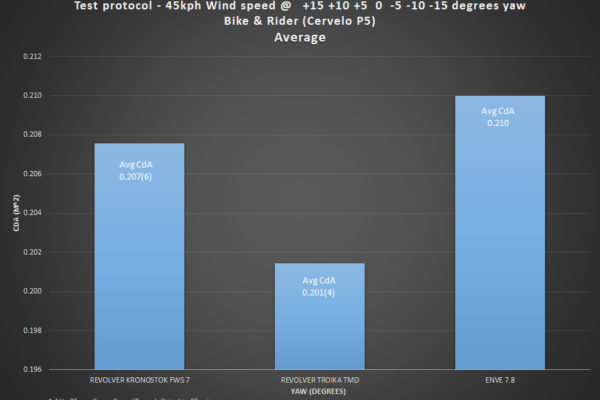

We use three reliable facilities, the R J Mitchell located at the University of Southampton, the Boardman Performance Centre and the latest Silverstone facility. These are cycling specific and testing is carried out at the relevant wind speeds and angles or ‘yaw’ typically encountered by a racing cyclist. Typically the subject rider is pedalling, wheels are in motion so we can gather data as close to real world conditions as possible. CdA (Coefficient of drag) is measured and averaged from hundreds of readings within each test condition undertaken. These readings can then be converted into time savings or losses for each test variable. What we must remember here is that as previously mentioned these test conditions are controlled for accurate comparisons but the predicted time savings achieved in the tunnel aren’t always fully realised on the open road in race conditions. Variables such as gusting or swirling winds, traffic pushing and pulling forces and the inability to maintain that perfect position while negotiating technical areas or through fatigue all have an immeasurable impact.